Flexistop Case Study

The roof pictured here is that of a listed, “Art Deco” period residence which was covered with asphalt and was leaking in a number of places.

The entire roof, including a covered walkway with several rooflights, was repaired by MSP Coatings, using FlexiStop.

The work was completed in less than a week without any disruption caused to the owners or their family: life carried on as normal while we fixed the roof.

Flexistop Roof Coating Material

In the flat roof pictured (below), a small leak in the gutter is one of three issues causing the roof to leak. The existing roofing material, a preformed membrane, has been perforated in a number of places and needs to be replaced or recovered. The membrane around a number of small ventilation units is torn. Either torch-on bituminous felt or another layer of the uPVC membrane needs to be brought onto the roof, cut into shape (tailored, you might say) and heat welded into place.

Also, the outlet from the rooftop water tank is leaking and the weight of the tank itself is threatening the integrity of the membrane it is resting on. This is going to require a lot of work to repair the roof correctly! Rolls of felt or pre-formed membrane. Torches, gas-tanks, the lot. Still, roofers are used to such inconvenience. So they don’t mind…

But the business owner does mind! The pictures are of a flat roof extension to the rear of an old, city-centre building. The only way to get large rolls of roofing materials and equipment onto the roof is over the front slated hip roof of the original building, THREE FLOORS ABOVE STREET LEVEL, down the slope on the rear, and on to the flat surface where work can then begin.

This will require a scaffold to be erected on the busy city pavement, enclosing a series of ladders which will allow men and equipment to be brought to the third floor roof and over. Health and Safety issues regarding pedestrians, forced by scaffolding onto the roadway, must be addressed. The cost of all this has the owner scratching a head that, after many years of global recession, is already well scratched. He is thinking, “I really don’t need this. That bucket collecting water, sitting in the middle of the office floor, is not really such an inconvenience. And we can live with that yellow stain on the wall for another year or two. Or three…”

So the roof continues to leak water and the roofer looks for work elsewhere…

But wait! A small skylight in a top floor store-room allows limited, restricted access to the flat roof. The size of the gas tank is a no-go. What to do? The problem with the roof is now caused by the roofing materials themselves… MSP Coatings’ roofing solution products have the answer…

Three 5 Litre cans of FlexiStop quality roofing product, a couple of paint brushes and a 4″ roller pose no access problems, and from start to finish the flat roof is repaired in nine hours.

After the surface had been cleaned and dried, FlexiStop Liquid Silicone Roofing Material was brushed straight from the can on to the affected areas: along the horizontal, up the slope; around, and up on to the ventilation shafts. Two new outlet pipes are fitted into the gulley and sealed with FlexiStop. When fully cured, two hours later, the FlexiStop Roofing Material has completely adhered to, and bonded with, all the different surfaces, forming a single, seamless waterproof membrane. FlexiStop sticks to, and repairs, almost every known roofing product. And FlexiStop Roofing Material is also Fire Resistant (BS 476 & BS 6853).

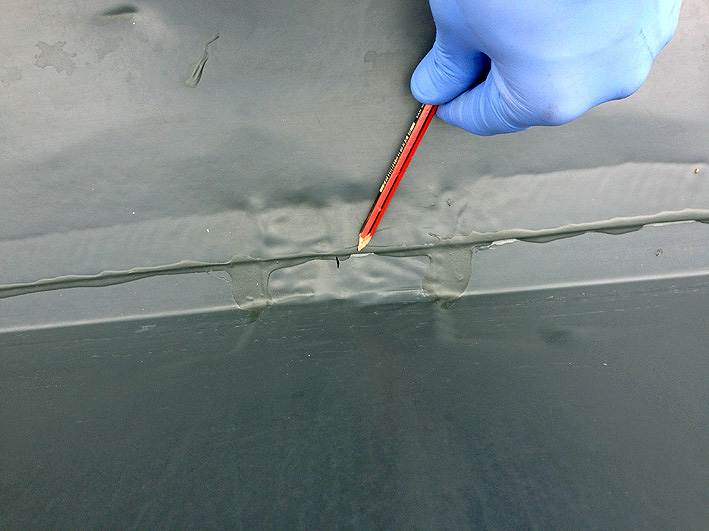

The leaking water outlet has been sealed with a coat of FlexiStop, as has the joint between two sheets of uPVC membrane which were beginning to part company, and water would soon start leaking through to the office below in a very short time (another bucket on the office floor).